DELIVERY IN THE WAKE OF DESTRUCTION

Even before hurricanes Harvey and Irma disrupted the flow of America’s business, the nation’s transportation and logistics capacity was strained. The aftermath of the storms amplified distribution challenges, and highlighted the need for the reliability of asset-based transportation providers and comprehensive logistics solutions that include other elements of the supply chain mix.

THE ADVANTAGE OF A LOGISTICAL ALLY

While events such as Harvey and Irma can’t be scheduled or avoided, there’s an undeniable advantage to having a contingency plan already in place and relying on a capable, dependable logistics partner to help you minimize the impact. A truly proactive partner will help you assess your supply chain’s points of vulnerability to disruptions and help you develop an efficient, viable strategy to offset them. Transportation agents and brokers by definition do not directly control the resources needed to effectively execute on your plan, so you will be wise to partner with an asset-based provider who can give you the assurance of resource availability when you need it most. Another absolute necessity is selecting a partner equipped with the latest technology for monitoring the status in real-time of the loads in transit, driver safety, and equipment performance and efficiency.

Creating long-term strategic relationships with asset-based transportation partners is the key to staying ahead of your competition and keeping your products in your markets when disaster strikes or drivers get hard to find.

The ideal contingency plan should consider critical factors and resources, including transportation equipment availability and capacity, drivers, warehouse space, labor and beyond. A reliability analysis follows, determining how to deliver on time while observing driving safety, regulatory compliance, and the safety of the goods in transit. A strategy to prevent freight theft is crucial. During stressful, chaotic times, load security – as well as maintaining proper insurance coverage and risk protection – become paramount.

The best logistics partner understands the need for real-time updates of load and inventory information. Advanced monitoring technology provides more than goods-in-transit visibility to clients, it provides peace of mind those clients can pass on to their customers. It can turn a nerve-wracking event, into an opportunity to build trust and strengthen relationships.

Today’s logistics partner becomes tomorrow’s irreplaceable ally when you are willing to work closely with them to understand your distribution priorities. A relentless dedication to improved capacity, coordination, efficiency, visibility, security and safety manifests as the ultimate in peace of mind. You’ll find your concern for future crises evolving into confidence in their ability to take charge no matter what mother nature throws at the world.

DRIVER SHORTAGE THREATENS DELIVERY RELIABILITY

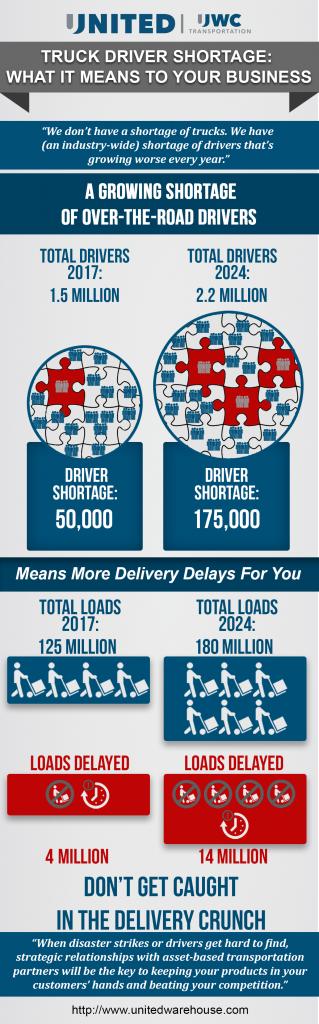

We are facing a capacity crisis in the trucking industry. But we don’t have a shortage of trucks. We don’t have a shortage of trailers or equipment. We have a shortage of drivers that’s growing worse every year. And “driverless trucks” won’t have any noticeable impact for the next 10 years.

We don’t have a shortage of trucks. We have (an industry-wide) shortage of drivers that’s growing worse every year.

Transportation rates following the hurricanes escalated dramatically due to the urgent change in demand, but also driven by this chronic and growing driver shortage. Both rates and delivery reliability are bound to be negatively affected as the driver shortage grows–estimated to more than triple from -50,000 in 2017 to more than -175,000 in 2024.

Creating long-term strategic relationships with asset-based transportation partners is the key to staying ahead of your competition and keeping your products in your markets when disaster strikes or drivers get hard to find.